Powder Coating Equipment Repair

Parker Ionics powder coating guns, hoppers, booths, and accessories are some of the most efficient and durable technologies in the industry. Advanced powder coating equipment provides a robust coat to metal surfaces. These systems comprise various essential components, such as pumps, ovens, and conveyors. Maintaining the powder coating system is crucial to ensure its longevity and efficiency.

But when they do need repair, it's best to have it done by Parker Ionics. We stand by the quality of our products, and no other repair company can offer comprehensive diagnostics or guarantee their repair and maintenance as we do.

Troubleshooting and Repair Techniques

Effective troubleshooting and repair techniques are essential for maintaining the performance and productivity of powder coating equipment. Common issues that may arise include clogged nozzles, faulty electrical components, and worn-out spare parts. Addressing these problems promptly through regular maintenance can prevent errors and ensure the equipment operates at its best.

The troubleshooting process involves identifying the source of the problem, diagnosing the issue, and implementing a solution. This may include replacing faulty components, cleaning and maintaining the equipment, and adjusting settings to optimize performance. Regular inspections and maintenance can help detect potential issues early, reducing the risk of unexpected downtime.

Professional service providers have the expertise and experience needed to handle complex repairs and ensure the equipment is functioning correctly.

By implementing effective troubleshooting and repair techniques, businesses can extend the lifespan of their powder coating equipment and ensure it continues to deliver high-quality results.

Maintenance and Prevention

Regular maintenance and preventive measures are vital for ensuring the optimal performance and longevity of powder coating equipment. Maintenance techniques include cleaning and maintaining the equipment, replacing faulty components, and adjusting settings to keep the system running smoothly. These practices help minimize downtime and maximize productivity, ensuring the equipment remains in top condition.

Prevention techniques involve regular inspections, troubleshooting, and timely repairs to address any issues before they escalate. By conducting routine checks and maintenance, businesses can prevent errors and ensure the equipment operates efficiently. This proactive approach helps avoid costly repairs and extends the lifespan of the equipment.

With Parker Ionics Repair Service, You Can Expect:

Our company is committed to supporting customers by providing high-quality equipment and services tailored to meet their needs.

- Problem resolution and expedited parts delivery from our warehouse located in Westland, MI USA, with expert support available for on-site repairs and troubleshooting

- Analysis, troubleshooting, and resolution of powder coating finish quality and operational issues

Our extensive experience designing and building industrial equipment, including ovens and paint booths, ensures that we deliver reliable, high-performing systems that meet customer expectations. Our equipment applies dry powder to metal surfaces to create a durable coat, enhancing the longevity and appearance of the finished product.

To request service on your Parker Ionics powder coating equipment, call (734) 326-7630.

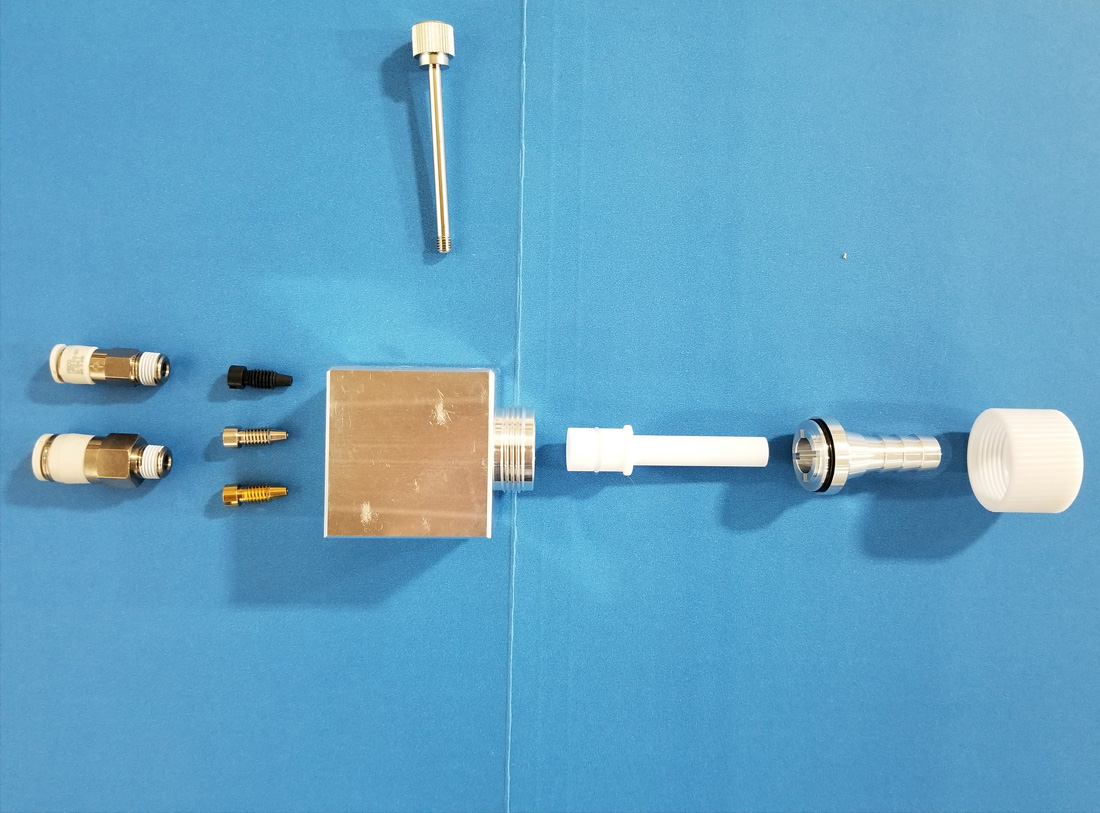

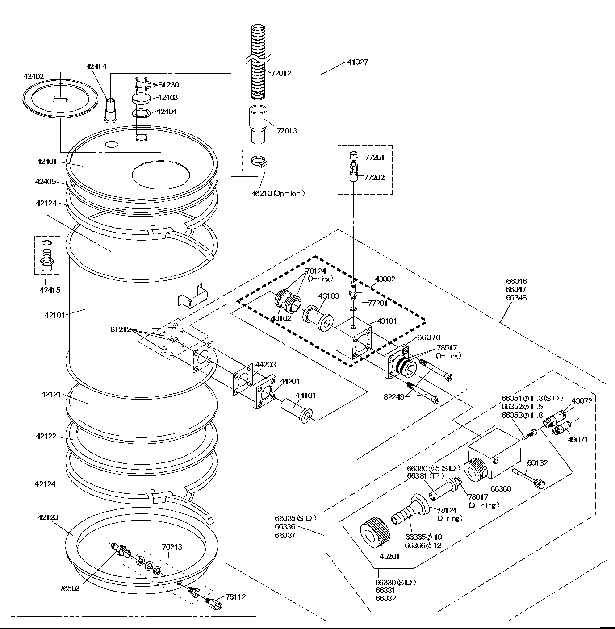

Replacement Parts for Parker Ionics Spray Guns and Powder Coating Equipment

Replacement Parts for Parker Ionics Spray Guns and Powder Coating Equipment